Filter Presses For Aggregate Plant Effluent

페이지 정보

작성자 Bailey 작성일25-01-09 08:03 조회2회 댓글0건관련링크

본문

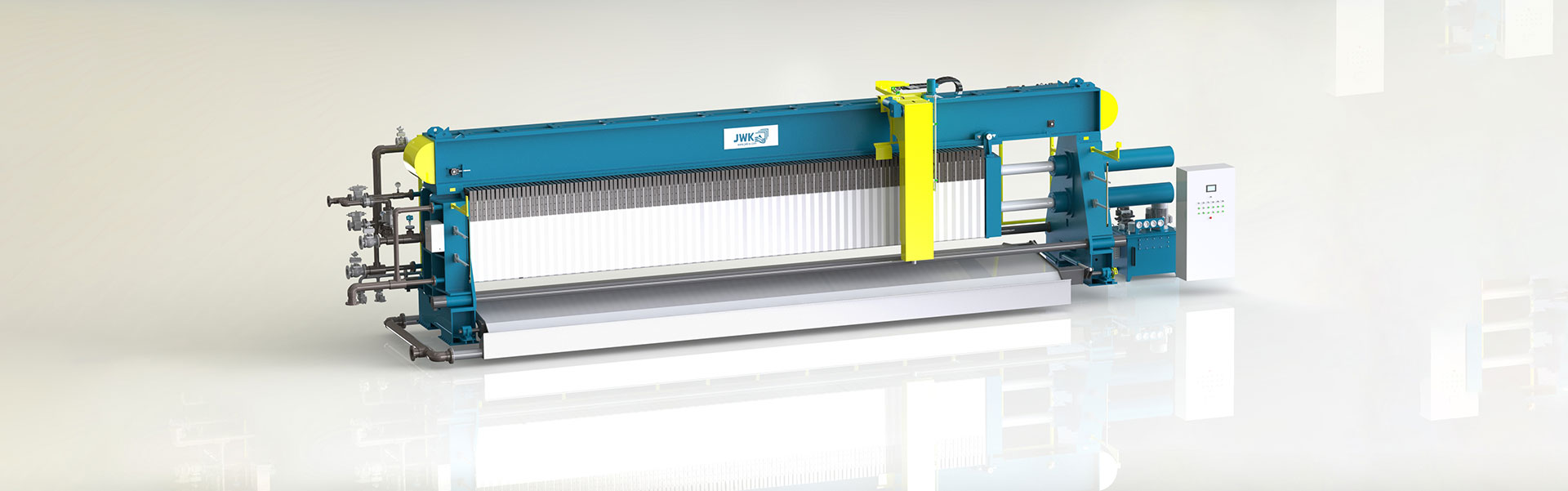

Depending on the clay content, recessed plates working at 225 psi sometimes produce cakes of 70 to eighty five per cent solids on aggregate tailings. Membrane plates may improve the share of solids and reduce cycle occasions while treating the identical slurry. The addition of membrane plates could also be thought-about if increased solids content will probably be required to fulfill compaction necessities. The selection of the correct cake thickness is also critical to the proper functioning of the press. Cake thicknesses usually vary from 15mm to 50mm. As the filter cake becomes thicker the permeability of the cake decreases. No parts on the sides of the press, allowing unobstructed access to vary filter cloths on the press with out plate removal. A much wider plate opening usually exceeding 0.9m (3?) between the plates.

The plates are connected to a hydraulic cylinder that's used to open and shut the press. The liquid to be filtered is pumped into the press and flows through the filter cloth or paper into the recessed chambers formed by the filter press machine manufacturers in india plates. As the liquid flows through the filter medium, solids are trapped on the filter cloth or paper, forming a filter cake. As soon as the press is full, the hydraulic cylinder is activated to shut the press, applying stress to the filter cake. The pressure helps to take away more liquid from the filter cake, leading to a drier cake.

Space Manufacturing: Chemical programs off-earth are being explored for potential functions in house manufacturing. Meals Trade: Chemical processing tools is used within the meals trade for numerous processes, including pasteurisation, sterilisation, and extraction. Waste Administration: Chemical engineers are also involved in waste management and analysis. Power Sector: In the vitality sector, chemical processing systems are used within the manufacturing of biofuels and in the refinement of crude oil. "The GHT5000F Domino can considerably enhance the capital price of a tailings filtration plant in contrast with installing many smaller filter presses for the same operation," stated Collini. "On a case-by-case basis, it is feasible to evaluate the total cost of possession. Meanwhile, work is continuing on the new plant in Lugo, which will allow Diemme to more effectively handle quite a few difficult filtration tasks that are currently in the pipeline.

M.W. Watermark™ understands that when your filter cloths should be replaced, day-after-day that you've to wait for brand spanking new cloths is costing you. That’s why we make ordering filter cloths as easy and as streamlined as attainable, allowing you to get your operation again up and running rapidly, with minimal downtime. Q: What are head cloths, intermediate cloths, and tail cloths? Today’s automated filter press improves production time and is a reliable resolution to the particular problems related to the dewatering of mineral process slurries. With decrease upkeep prices of traditional filter presses and better performance, it is rising more and more standard in a wide range of industries, including stone fabricating and metal ending. Most models might be integrated seamlessly into current wastewater filtration techniques, use much less water in processing, and permit for unprecedented precision manufacturing.

댓글목록

등록된 댓글이 없습니다.