Examples of the Thermoplastic Resin Are

페이지 정보

작성자 Reda 작성일24-12-16 01:41 조회4회 댓글0건관련링크

본문

The 1394 cable normal defines three signaling rates: 98.304, 196.608, and 393.216 Mbps (megabits per second; MBps on this paper refers to megabytes per second.) These charges are rounded to 100, 200, and 400 Mbps, respectively, in this paper and are referred to within the 1394 commonplace as S100, S200 and S400. Map for specific node pairs, the bus can help a number of signaling speeds between particular person pairs. The capabilities of the 1394 bus are adequate to assist a variety of excessive-end digital audio/video purposes, corresponding to client audio/video system management and sign routing, residence networking, nonlinear DV editing, and 32-channel (or extra) digital audio mixing. Consumer DV gear uses S100 speeds, however most 1394 Pc adapter cards assist the S200 price. Although melt viscosity of the kind II is 6 to 7 instances greater than that of the kind I, the kind II is appropriate for uses necessitating durability as a result of the kind II could be employed in an extrusion molding. The tetrafluoroethylene-perfluoroalkylvinyl ether copolymer is prescribed in ASTM D 3307, and has two varieties, Facebook i.e. Type I and type II. The two twisted pairs are crossed in each cable meeting to create a transmit-receive connection. This cable is supposed for very outdated hardware, and i do not advocate constructing one until you even have such hardware.

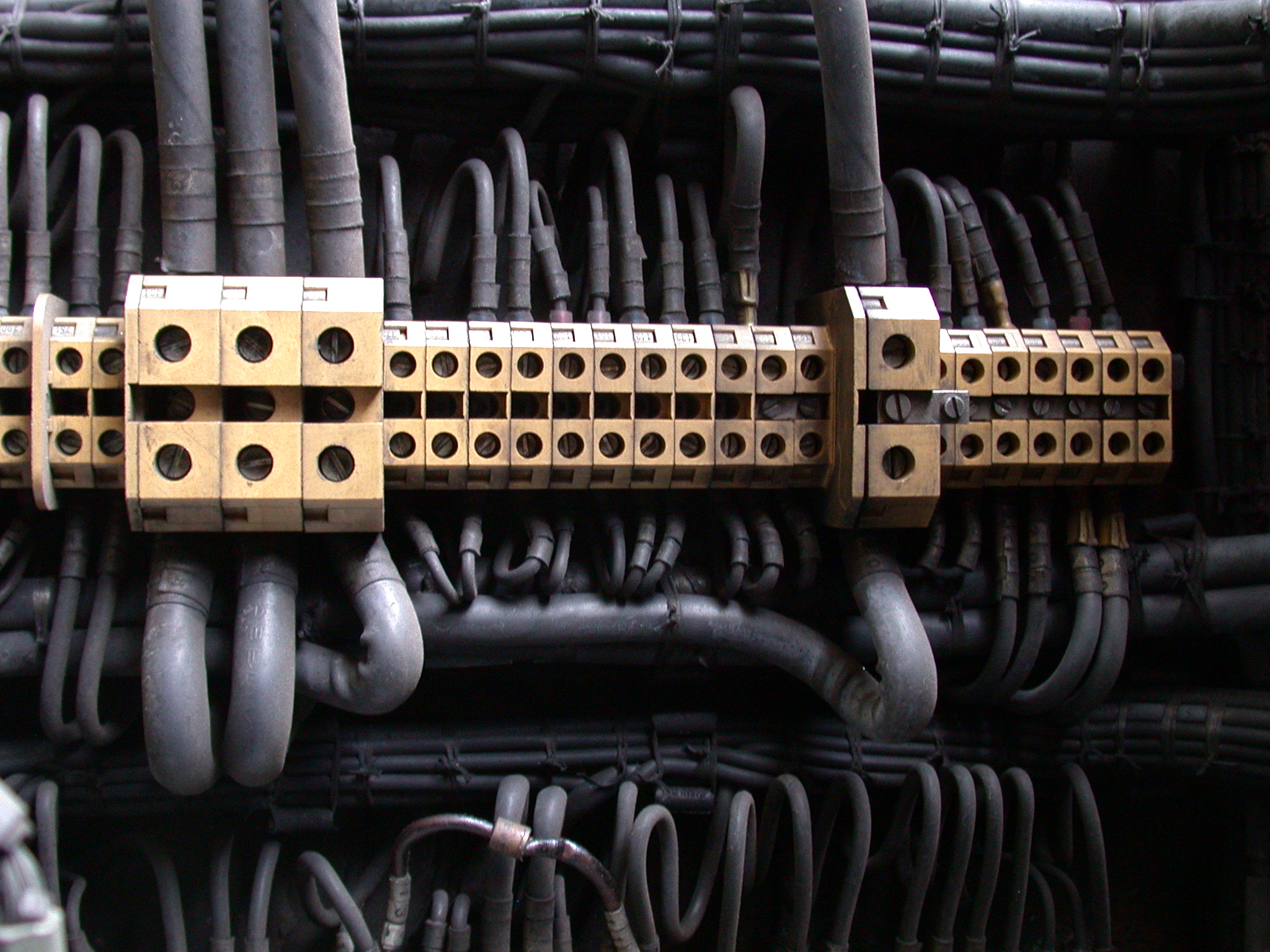

Seven steel wires are twisted to acquire one strand, and seven strands are twisted to acquire a wire rope with 7.times.7 building and an outdoor diameter of 3.0 mm. When the paste-extrusion technique is employed, it is preferable that paste is prepared by adding kerosene to polytetrafluoroethylene powder and kneading them, the paste is extruded to give a tube underneath high stress and a stranded steel wire is coated with the tube, and after that, shield control cable the stranded steel wire is dried and baked in a furnace equivalent to an electric furnace. It is necessary that the particle size of the powder is 5 to one hundred fifty .mu.m. When the particle measurement is greater than one hundred fifty .mu.m, a uniform skinny film can't be formed. When the particle size of the powder is less than 5 .mu.m, a pinholl is well generated because the powder is agglomerated. As a method for forming an internal coat through the use of the polyphenylene sulfide, for example, a melt-extrusion methodology and an electrostatic coating methodology of powder could be cited. Attach the wires from the 4 conductor cable to the DB25 pins, utilizing the earlier color code as a guide. Using a multi-meter on DIODE (continuity) check, measure between the pins on the chart beneath.

Seven steel wires are twisted to acquire one strand, and seven strands are twisted to acquire a wire rope with 7.times.7 building and an outdoor diameter of 3.0 mm. When the paste-extrusion technique is employed, it is preferable that paste is prepared by adding kerosene to polytetrafluoroethylene powder and kneading them, the paste is extruded to give a tube underneath high stress and a stranded steel wire is coated with the tube, and after that, shield control cable the stranded steel wire is dried and baked in a furnace equivalent to an electric furnace. It is necessary that the particle size of the powder is 5 to one hundred fifty .mu.m. When the particle measurement is greater than one hundred fifty .mu.m, a uniform skinny film can't be formed. When the particle size of the powder is less than 5 .mu.m, a pinholl is well generated because the powder is agglomerated. As a method for forming an internal coat through the use of the polyphenylene sulfide, for example, a melt-extrusion methodology and an electrostatic coating methodology of powder could be cited. Attach the wires from the 4 conductor cable to the DB25 pins, utilizing the earlier color code as a guide. Using a multi-meter on DIODE (continuity) check, measure between the pins on the chart beneath.

Solder bridge pins 18 to 25 on the DB25 connector to make the bottom strip. There ought to be a short between each of the pins from one connector to the other. When the melt index of the polyoxymethylene is less than 0.5 g/10 minutes, moldability deteriorates because there is a necessity to heat the polyoxymethylene to nearby a temperature of the thermal decomposition. Accordingly, it is preferable that the melt index is 0.5 to 5 g/10 minutes. The tetrafluoroethylene perfluoroalkylvinyl ether copolymer and the tetrafluoroethylenepentafluoroproylene copolymer may be employed in an extrusion molding by heating to melt. Among them, polytetrafluoroethylene, tetrafluoroethyleneperfluoroalkylvinyl ether copolymer and tetrafluoroethylene-hexafluoroethylene copolymer, specifically, polytetrafluoroethylene are ideally used because they're wonderful in thermal resistance, load efficiency and suppleness. Within the method, F denotes a price of a load cell on the enter end and W denotes a worth of a load cell on the output end. A load cell 14 was linked with the internal cable 1 on the way at the input facet, and one other load cell 15 was connected with the internal cable 1 on the way on the out put side. The interior coat 3 of which thickness is about 0.35 mm is coated on the skin surface of the inner cable 1. The surface diameter of the interior coat three is 3.7 mm.

Next, the liner was inserted into a conduit having a protecting layer fabricated from polypropylene of 0.7 mm in thickness on the skin surface of a springy armor layer having an outside diameter of 8.6 mm. A thermoplastic resin proven in Tables 1 to 4 was heated to melt, and the organopolysiloxane obtained within the above was added thereto in a proportion proven in Tables 1 to 4. After they have been uniformly kneaded, a liner having an inside diameter of 4.6 mm and an out of doors diameter of 5.6 mm was molded. Among the thermoplastic resins used in the interior coat, polybutylene terephthalate, excessive density polyethylene, polyoxymethylene and polyphenylene-sulfide are significantly preferable as a result of these are wonderful in abrasion resistance. The polyoxymethylene is excellent in abrasion resistance and has a low abrasion coefficiency. Representative examples of the polyoxymethylene are, as an example, DELRIN commercially obtainable from Du Pont, Celcon commercially accessible from Hoechst Celanese, and the like. The polyoxymethylene additionally has properties equivalent to low stickslip under a excessive load and improves the operationability of a management cable.

댓글목록

등록된 댓글이 없습니다.